One of the most supplied in Chuan Kok’s product range is stainless steel pipes. Stainless steel pipes are consumed in high performance fluid or gas line application. Most clients requests for seamless stainless steel pipes due to their corrosion resistance and ability to withstand pressure.

Introduction:

Chuan Kok keep stock for seamless stainless steel pipes in dual grade SS316/SS316L. The stainless steel pipes are in accordance to ASTM A312. ASTM A312 is the standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipe.

Stainless Steel Pipe Attributes:

The minimum tensile strength for stainless steel pipes is 515 N/mm² while minimum yield strength at Rp 0.2% at 205 N/mm². Stainless steel pipes contain at least 10.5% of chromium. This allows it to form an invisible chrome-oxide layer by reaction with oxygen.

SS316/316L is a chromium-nickel-molybdenum bearing austenitic stainless steel. The molybdenum content in stainless steel pipe is around 2.0% to 3.0%, while nickel content is around 11% to 14%. The nickel and molybdenum content provides great corrosion resistance in corrosive surroundings, such as salt water or chloride environments. In addition, SS316/316L material will reduce the tendency of the material to crack after welding. It also provides higher tensile strength at elevated temperature.

The meaning of “L” designation in SS316L grade is that carbon content is restricted to 0.03% where the normal carbon content in stainless steel SS316 is 0.08%. The lesser the carbon content the stainless steel has, the greater it is in weldability. And it also prevents chromium from being depleted, thus, it can still form the chrome oxide layer on the pipe surface.

Stainless Steel Pipe Finishing:

Pipes are supplied in 1 type of finishing which is Annealed and Pickled. Annealing is a heat treatment that alters the physical and chemical properties of the material. It also increases the ductility and reduces the stainless steel pipe hardness. Pickling is a metal surface treatment that contains acid to remove the impurities on the pipe surface.

Stainless Steel Pipe’s Pipe Ends:

There are 3 main types of pipe ends for stainless steel pipe, namely plain end (PE), bevel end (BE) and threaded end (TE).

Plain end pipes are pipes that with unfinished ends. Generally, plain end pipes are used for small diameters pipe systems. It also suitable for socket weld fittings and flanges.

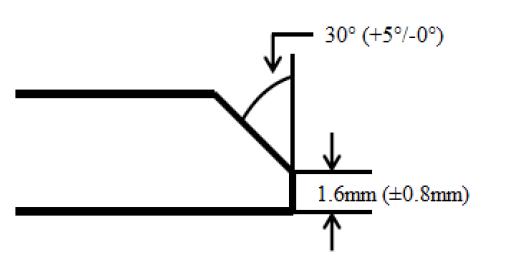

Bevel end pipes are pipes that have a standard angle of 30° (+5°/-0°) on the pipes end surface. It also has a root face of 1.6mm (±0.8mm). However, pipes with non-standard angles can also be produced. Bevel end pipes are usually used for butt weld fittings and flanges where they can be directly welded to each other. Picture of bevel end are illustrate as below.

Threaded end pipes are pipes that with tapered groove that cuts into the ends of pipes. The tapered groove allows the pipes to be easily assembled with threaded fittings. The standard thread for tapered groove is National Pipe Thread (NPT). As NPT connections are assembled, it will reduce the possibility of leakage.

Outer Diameter and Wall Thickness Specifications:

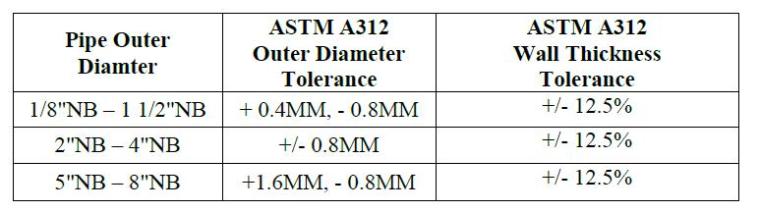

Pipes outer diameter (OD) is in accordance to ASTM A312. The tolerance of pipe outer diameter and wall thickness are as below:

From table above, for pipes OD that range from 1/8″NB – 1 1/2″NB, the standard OD tolerance is +0.4mm, -0.8mm. For Chuan Kok’s pipe sizes 1/8″NB – 1 1/2″NB, we control the OD tolerance to be ±0.4mm. For 2″NB – 4″NB, the standard OD tolerance is ±0.8mm to which our pipes comply. For 5″NB – 8″NB pipes, the standard OD tolerance is +1.6mm, -0.8mm.

For pipes wall thickness, the specifications are +/- 12.5%. However, we regulate the wall thickness to +/- 10%.

Stainless Steel Pipe Wall Thickness:

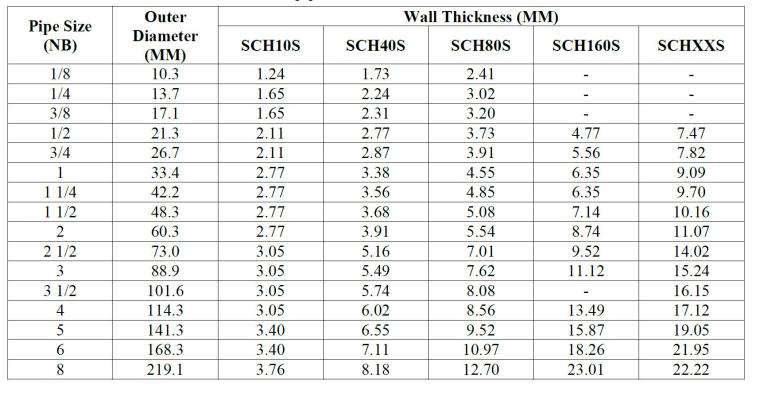

Wall thickness of stainless steel pipe is expressed in “schedules”, abbreviated as SCH. Thickness of stainless steel pipes can be divided to several groups such as SCH10S, SCH40S, SCH80S, SCH160S and SCHXXS. These represent different kind of thickness which depends on the pipe’s outer diameter (OD).

Please refer below table for stainless steel pipes wall thickness.

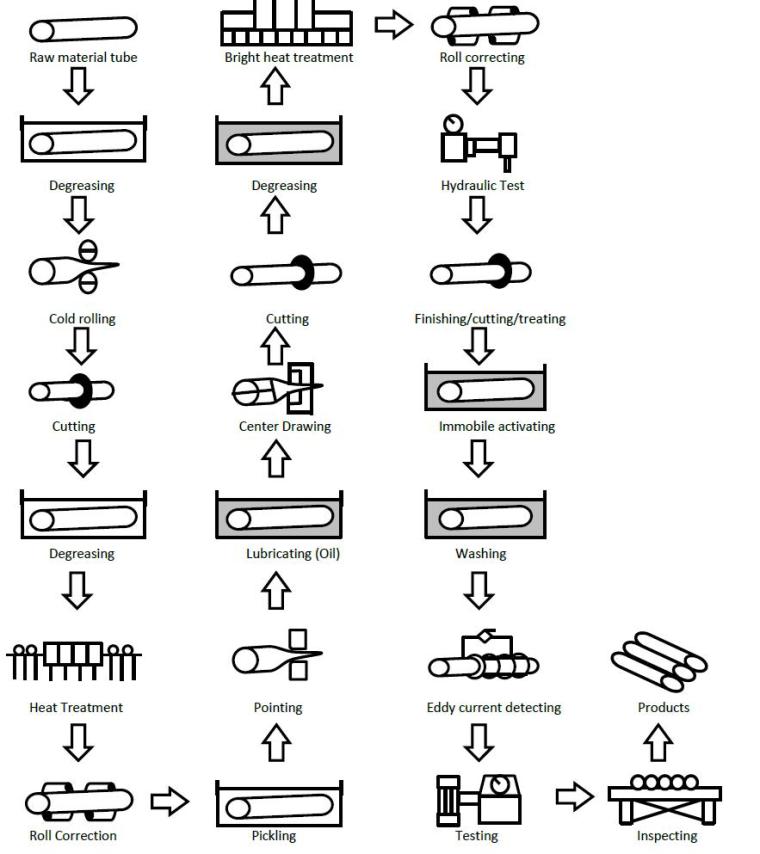

Stainless Steel Pipes Manufacturing Process

Chuan Kok Hardware maintains a large stock of stainless steel pipe to be needed in high performance hydraulic line application. Seamless cold drawn tubes are being constantly offered to clients due to its quality and cleanliness. Seamless cold drawn pipes are precision in dimension and free of scale. To find out more about Stainless Steel Pipes, do visit us at www.chuankok.com/stainless-steel-pipes.html